The Hidden Challenge of Residues in Compounding Pharmacies

Effective residue management ensures compliance and patient safety.

Residues in compounding pharmacies pose a significant challenge, potentially impacting safety and efficacy. Understanding what residues are, where they come from, and how to manage them effectively is crucial for maintaining a clean and compliant environment.

Residues in pharmacies primarily originate from two sources: compounding preparation processes and cleaning/disinfection activities. Compounding processes involve various substances, such as active pharmaceutical ingredients (APIs), buffers, media, and excipients, which can contribute to residue on work surfaces. On the other hand, cleaning and disinfecting activities introduce residues from detergents and disinfectants. Different disinfectants can leave various amounts of residue depending on the chemistry, and disinfectants with the same active ingredients can also have varying amounts of residue. Factors such as the concentration of active ingredients, stabilizers, preservatives, pH adjusters, and odor mitigators can influence the residue level.

Impact of Residues on Cleanrooms

Residues can have significant impacts on cleanrooms. Environmentally, they can create slip and fall hazards. Mechanically, they can interfere with proper disinfection and potentially corrode equipment. Aesthetically, residues on surfaces like windows and polished metals can affect the overall cleanliness perception of the facility. Regulatory compliance is another critical aspect of residue management. For instance, USP<797> requires residue removal of disinfectants in Primary Engineering Controls (PEC) with sterile 70% IPA and removal of residue and debris that may interfere with disinfection.

Residue Characteristics and Surfaces

Residues can vary significantly in appearance and behavior, taking different forms. Different surfaces, such as 304 SS, 316 SS, powder-coated steel, aluminum, and high-pressure laminate, can exhibit residues differently. Depending on the surface's characteristics, the same amount of residue can look very different.

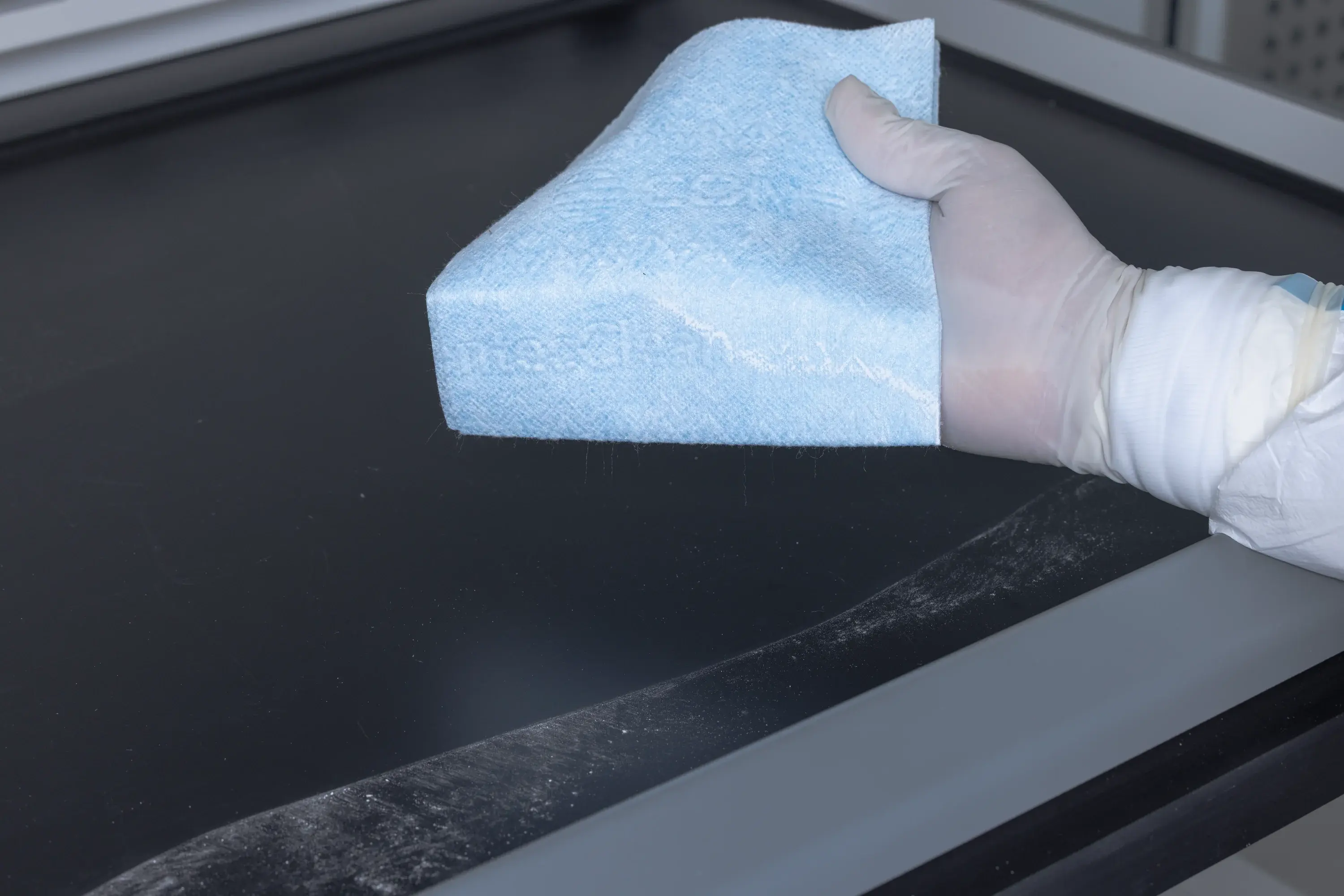

Effective Methods of Residue Removal

Effective residue removal methods are crucial. Some textiles are better for cleaning than others, with polyester cellulose being effective in pick-up and absorbency. Residue should be wetted or resolubilized for better removal, followed by a dry wipe. Built-up residue may require additional wiping. The solubility of the residue must be considered for effective removal. Solubilization requires using the correct solvent based on the residue chemistry. A toolkit for residue removal might include dry polycell wipes, pre-saturated polycell wipes, sterile 70% Isopropanol (IPA), and sterile water.

Control Practices for Residue Management

Residue management in compounding pharmacies involves both prevention and removal. Preventing residue build-up is better than correcting it, emphasizing the importance of maintaining regular cleaning and control practices. Understanding the nature of residues, their sources, and effective removal methods is crucial for maintaining a clean and compliant environment in compounding pharmacies. By implementing proper management practices, pharmacies can ensure both safety and efficacy in their operations.

.png)

.jpg)

-1.png)